- NYLON ANCHOR

Views 30

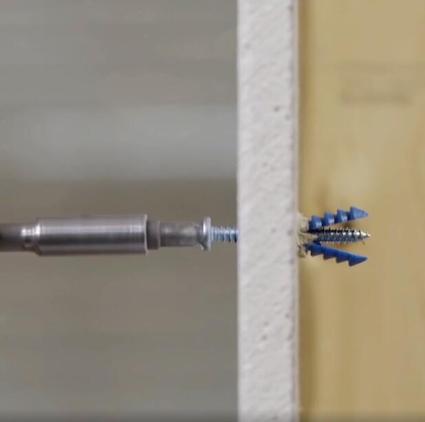

- WEDGE ANCHOR, THROUGHT BOLT

Views 17

Anchor fasteners are used to connect structural elements of base material to masonry and concrete in buildings and structures. They are installed by first drilling a hole in the base material. The hole is slightly larger than the fastener. Then the anchor is inserted into the hole in the right manner. Mechanical anchor fasteners use friction to anchor themselves in place. It is used to expand in diameter when it is pushed into the hole. This expansion grips the base material tightly and causes the anchor to be firmly wedged in place. Today, a variety of anchors are available to meet different applications. Mechanical anchors generally fall into two categories, Cast-in-place and Drilled-in anchor fasteners. Mechanical expansion anchors – can be loaded immediately after installation. Steel expansion anchors generally have better resistance to heat or fire. They can be further divided into two categories torque-controlled which is inserted into the hole and secured by applying a specified torque to the bolt head or nut with a torque wrench and displacement controlled which consist of an expansion sleeve and a conical expansion plug, whereby the sleeve is internally threaded to accept a threaded element. Clamping anchors – used to anchor two or four core insulated bundled cables, all of which have equal cross-sectional areas. The clamp is tightened by bolting and is designed to avoid damage to the cable insulation. The product can be used along with various types of hook bolts. Concrete wedge anchors – work by inserting them into a hole drilled into concrete. The concrete wedge anchor is then expanded, wedging itself securely in the concrete. These are available in zinc plated carbon steel for indoor dry applications, hot-dipped galvanized for most outdoor applications. This anchor helps prevent rust in dry environments; dependable application and maintenance.